Services

Streamlined Engineering Workflow: From Design to Maintenance

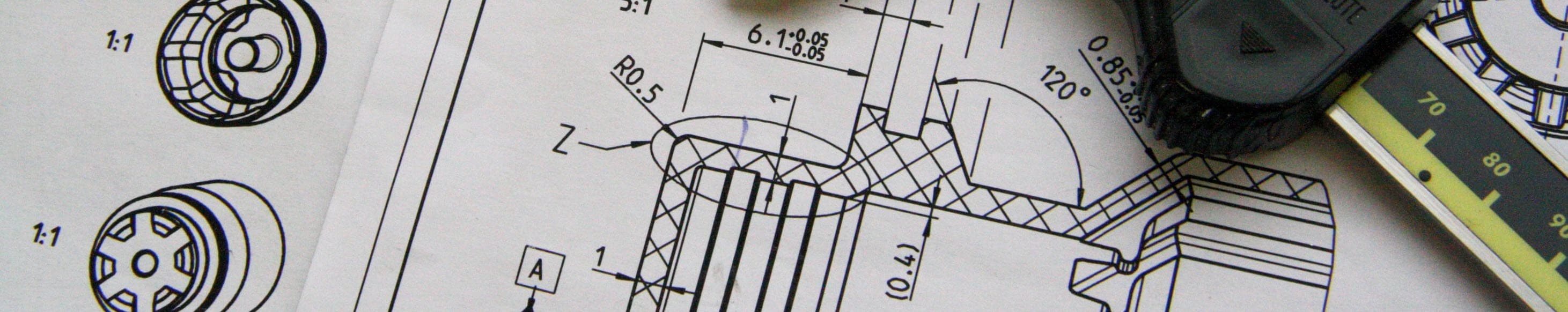

Thermodynamics: Design & Calculations

This phase focuses on using thermodynamics principles to create a foundational design. Engineers calculate heat transfer, energy efficiency, and other critical factors to ensure the system operates effectively under specified conditions.

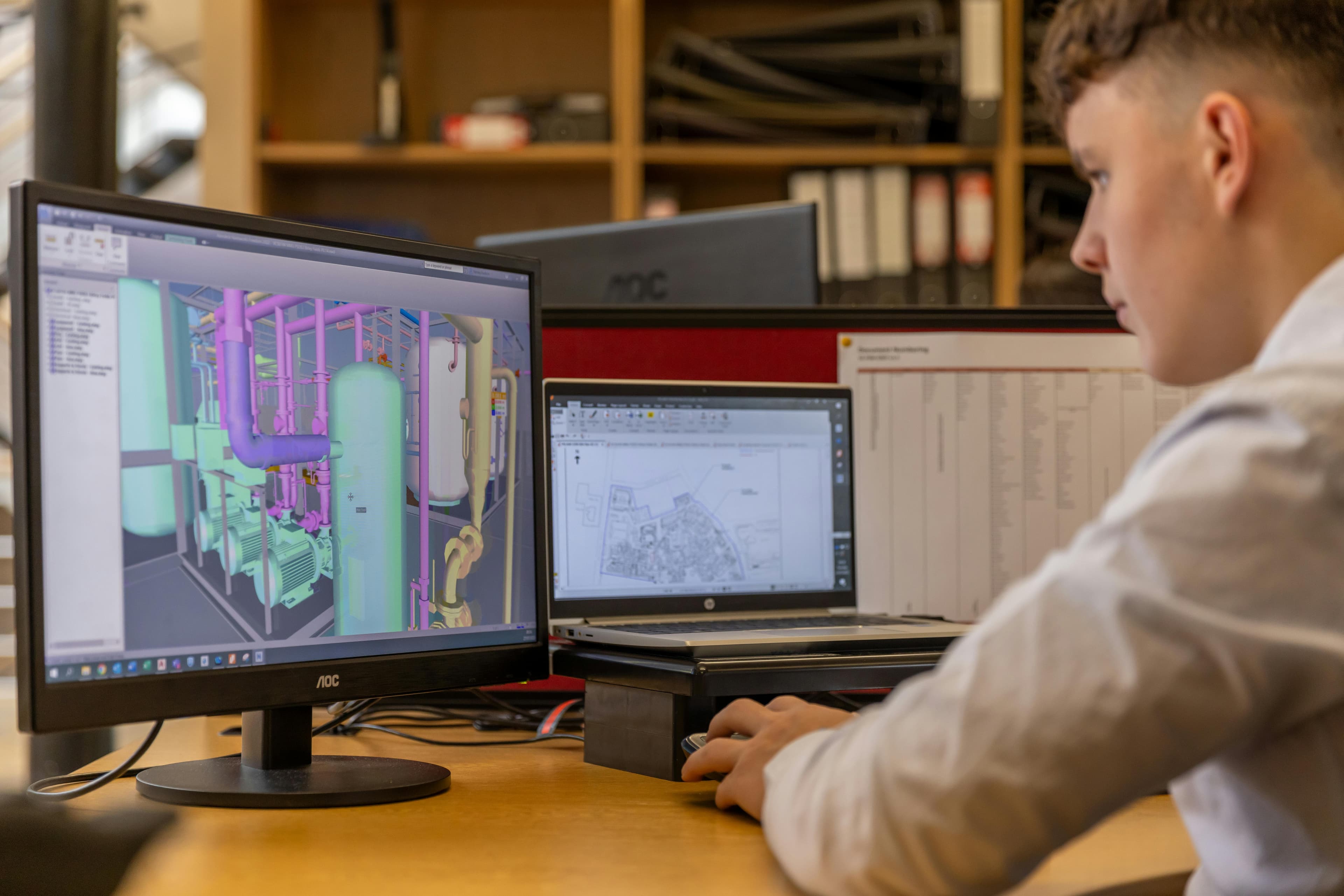

3D Modelling & Simulation

Engineers create detailed 3D digital models of the design, allowing for accurate visual representation and spatial understanding. This step helps in identifying potential design issues before moving to the physical prototyping phase.

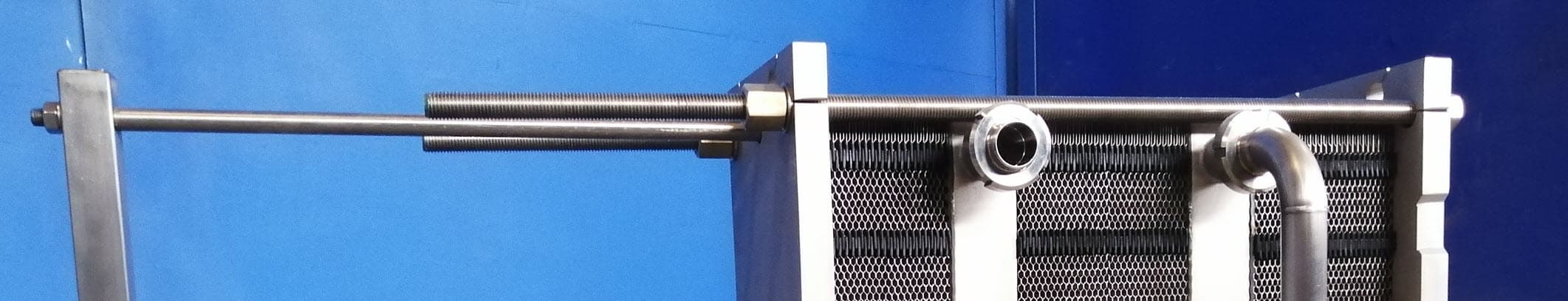

Prototyping

A physical prototype is built to test the design in real-world conditions. Prototyping ensures that the design is functional, reliable, and meets all the technical specifications. Adjustments are made based on testing results.

Mechanical Engineering

In this phase, mechanical engineering principles are applied to optimize the design. This includes refining the structure, materials, and mechanics of the system to ensure durability, efficiency, and cost-effectiveness.

Engineer to Order (ETO)

The system is custom-designed, built, and tested according to specific customer requirements and technical constraints. This involves incorporating customer feedback and making adjustments to meet their exact needs.

Installation & Maintenance

After the system is deployed, ongoing service and maintenance of heat exchangers ensure that the equipment continues to function efficiently. This step involves regular inspections, cleaning, and repair to extend the lifespan of the system.

At Carbon-Trim, we offer a comprehensive engineering process that takes your project from initial concept to final implementation, ensuring precision, efficiency, and customer satisfaction at every step. Our expert team handles every phase with attention to detail, using cutting-edge technology and industry expertise to deliver high-performance solutions tailored to your needs.

Contact Us